Metallic Ceramic Thermal Barrier Coating

Exhaust header coatings heat shield materials.

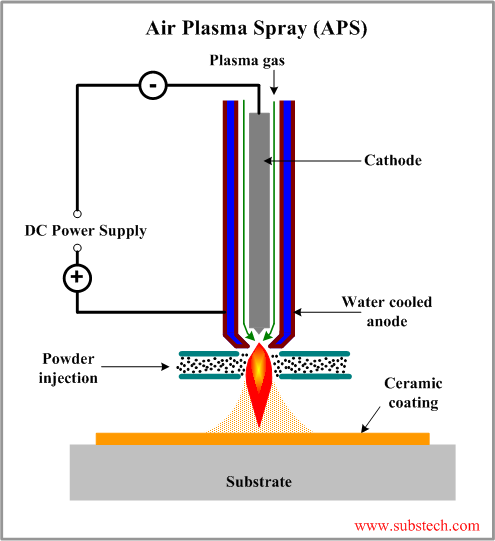

Metallic ceramic thermal barrier coating. Devices such as engine turbine blades can operate at high temperatures and can increase the thermal efficiency of devices engines etc by more than 60. Thermal barrier coatings tbcs provide effective thermal barrier to the components of gas turbine engines by allowing higher operating temperatures and reduced cooling requirements. The coating insulates the substrate material and lowers the substrate temperature. Wear resistant anti corrosion and aesthetic coatings finished in either ceramic or metal.

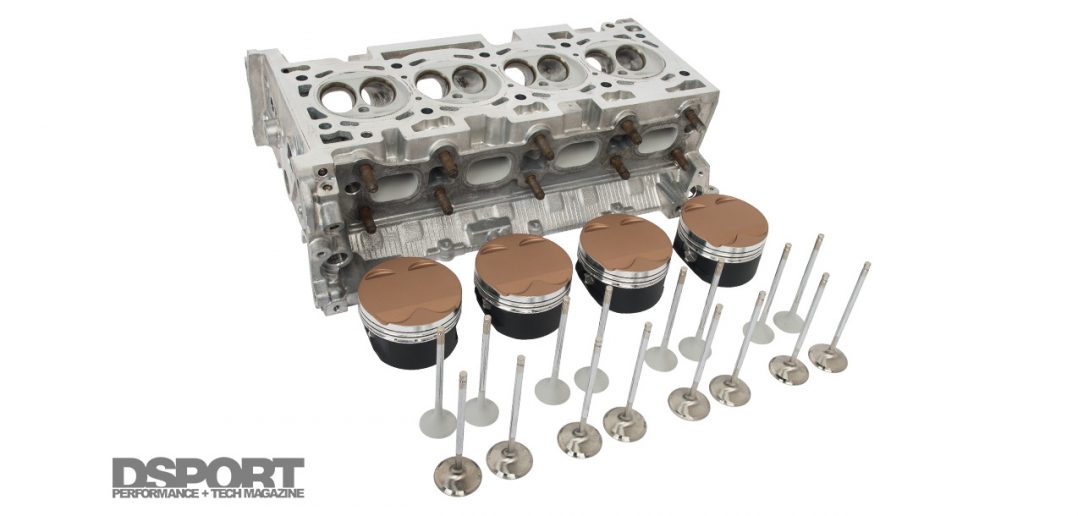

By doing so ceramic coating reduces under hood heat temperatures which will increase horsepower. So as to produce such a high level of protection thermal barriers incorporate many key parts. The most advanced exhaust system coating available. Thermal barrier coatings tbcs are advanced materials systems usually applied to metallic surfaces operating at elevated temperatures such as gas turbine or aero engine parts as a form of exhaust heat management these 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature.

It is a very durable ceramic reinforced coating available in a variety of colors. Thermal barrier coating tbc is a coating made of ceramic materials deposited on the surface of a high temperature resistant metal or superalloy. Each coating consists of 4 distinct layers with every layer adding to the protecting thermal properties and. Ceramic coating is an excellent thermal barrier.

Turbo charger housing coatings. Thermal barrier coating is designed to safeguard metal structural parts from extreme elevated temperatures thereby reducing stress and fatigue and increasing the part s period of time.