Mat 89 Ls Dyna

I m using lsprepost to check and setting model then i save it to keyword file k then i bring the file to ls dyna solver of ansys to solve it.

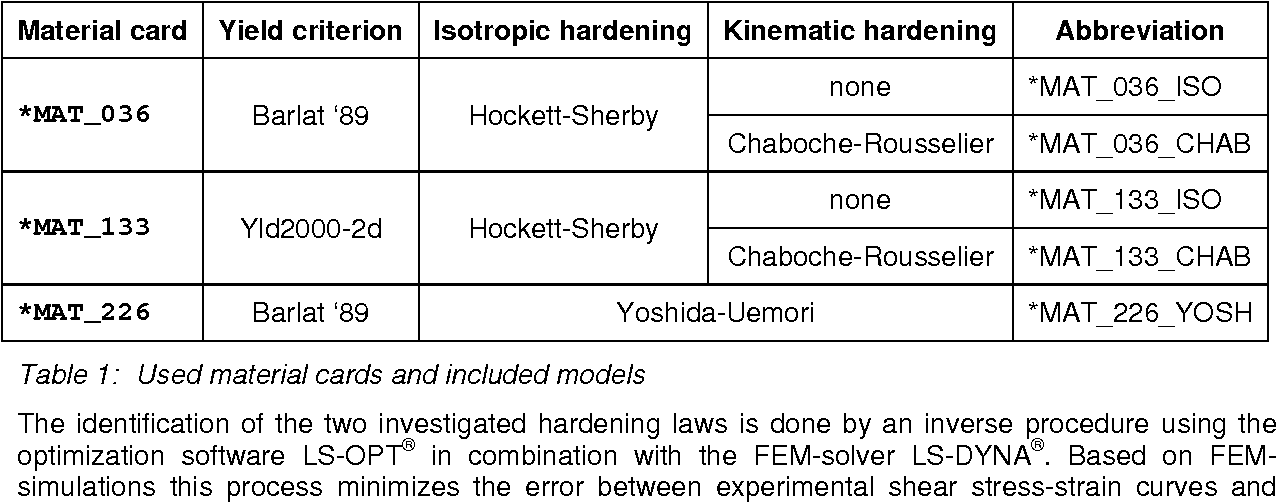

Mat 89 ls dyna. 0 solids 1h hughes liu beam 1b belytschko resultant beam. In this paper we cover the subject in more detail exploring in depth the nuances of commonly used ls dyna material models for plastics covering important exceptions and criteria related to their use. Anisotropic plasticity models are generally reserved for sheet metal stamping simulations using shells e. Mat 103 can be used with shells or solids.

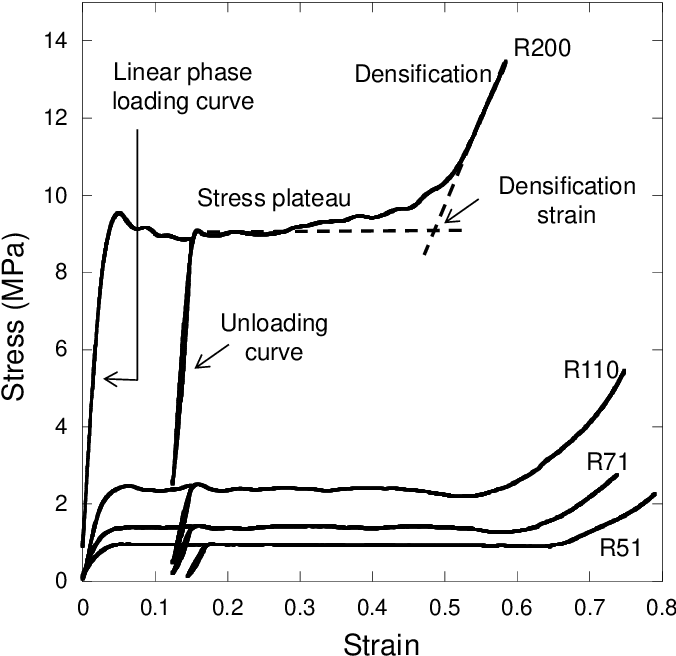

A center of mass is constrained to slide along a local coordinate system. Nominal stress and nominal strain from the tests must be converted to true stress and true strain. Plastics elastomers mat 24 mat 19 mat 89 material model ductile brittle transition. Ls dyna environment slide 24 composite materials in ls dyna composites webinar the main difference between the ls dyna orthotropic and composite materials is that for the composite materials an option for failure of fibres and matrix is available.

The numbers in brackets identify the element formulations for which the material model is implemented. Mat 33 mat 42 mat 39 same as. Other material models for metal stamping. The termination time is 0 010 seconds.

A little bit about my work. Plasticity polymer unlike other ls dyna material models both the input stress strain curve and the strain to failure are defined as total true strain not plastic strain. Mat ls dyna version 960 1 mat mat ls dyna has historically referenced materials by type identifiers. The input can be defined from uniaxial tensile tests.

Below these identifiers are given with the corresponding keyword name. 8theuropeanls dynauser conference strassbourg23 24 05 2011 sebastianmönnich 3 motivation. G mat 36 or mat 37.