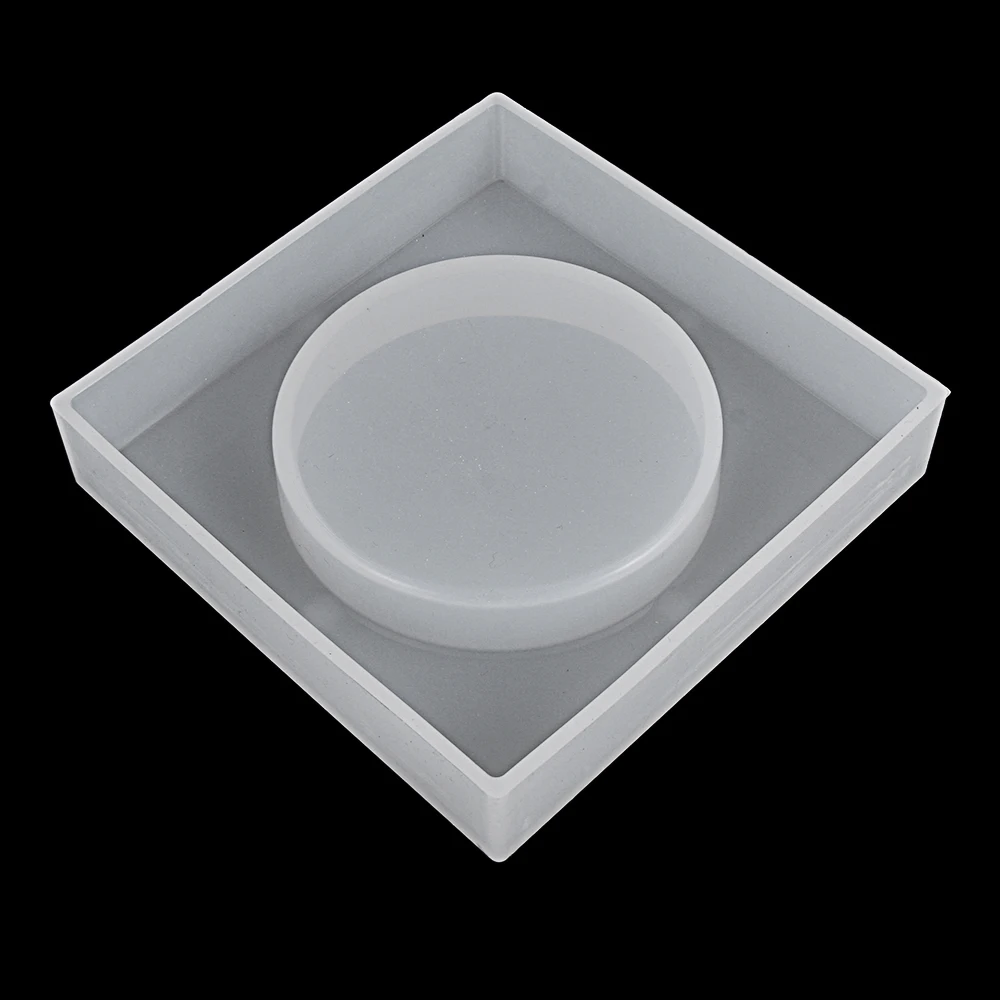

Molten Ceramic Plate Mold

The mold is filled with the molten material which will then cool and harden.

Molten ceramic plate mold. Ceramic shows we do not attend the ceramic shows. Allison c oct 29 18 at 20 03. It is used for castings as small as 30 g 1 oz to as large as 7 10 kg. 5 0 out of 5 stars 2.

After the wax is lost the mold is then ready to receive the molten metal. Once the metal has solidified the mold can be hammered in order to crack the sand and expose the metal object. The pattern a metal piece in the shape of the desired part is reused to form multiple shell. Get it as soon as mon sep 14.

With the massive loss of manufacturers attending ceramic shows you have to know. Used most commonly for the investment casting process the ceramic mold is created around plastic or wax that melts when the mold is fired while it is being created. Molten metal is poured into the ceramic mold through sprues or pathways and then once the metal has solidified into the shape of the mold the ceramic mold is cracked away and processing of the metal continues toward the final device. Both are kiln dried to prevent issues with steam and are used for high temperature media silver and bronze both melt at 1800 f.

Silver is commonly cast in plaster and bronze in ceramic molds. This keeps clay from sticking to them and helps reduce warping. Shell mold casting is a metal casting process similar to sand casting in that molten metal is poured into an expendable mold. Like sand casting plaster mold casting is an expendable mold process however it can only be used with non ferrous materials.

This is just how we make ceramic cups and plates. At the ceramic shop we carry a number of wooden drape molds which are lighter weight alternatives to plaster molds. However in shell mold casting the mold is a thin walled shell created from applying a sand resin mixture around a pattern. Ceramic mold another type of casting mold used with aluminum and other molten metals is the ceramic mold.

Plaster molds are used in pottery because they absorb water out of the clay as it dries. Plaster and clay ceramic are both commonly used as casting mold media. Plaster mold casting is a metalworking casting process similar to sand casting except the molding material is plaster of paris instead of sand. Ceramic molds are usually made out of plaster for use with liquid clay slip while some may also be used as presses for clay slabs.

Free shipping on your first order shipped by amazon. Like humps molds our slump molds are plaster templates that are useful for creating reproducible forms. During the firing the wax burns out of the ceramic. Investment casting is one of the oldest casting methods where molten metal is poured into a ceramic mold.

The molds that we currently carry are for forming slabs and or texturing slabs of clay and not slips of clay.