Moldbase Pocket Floor Best Finish Cnc Machining

Call today for cnc machining services in canada at affordable prices.

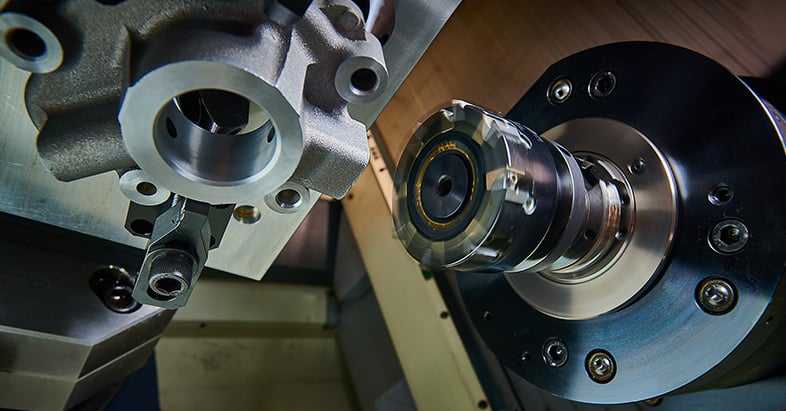

Moldbase pocket floor best finish cnc machining. Milling covers a wide variety of different operations and machines on scales from small individual parts to large heavy duty gang milling operations. In this article we ll be focusing on how to plan your first 2d machining project with 10 cnc milling toolpaths. But not always 2d profiling cuts vertical walls around the outside of a part for example. Due to the subtractive nature of cnc minor tool marks will be visible on the surface of the part after machining a number of post processing and finishing methods can be applied to improve the surface roughness visual properties and wear.

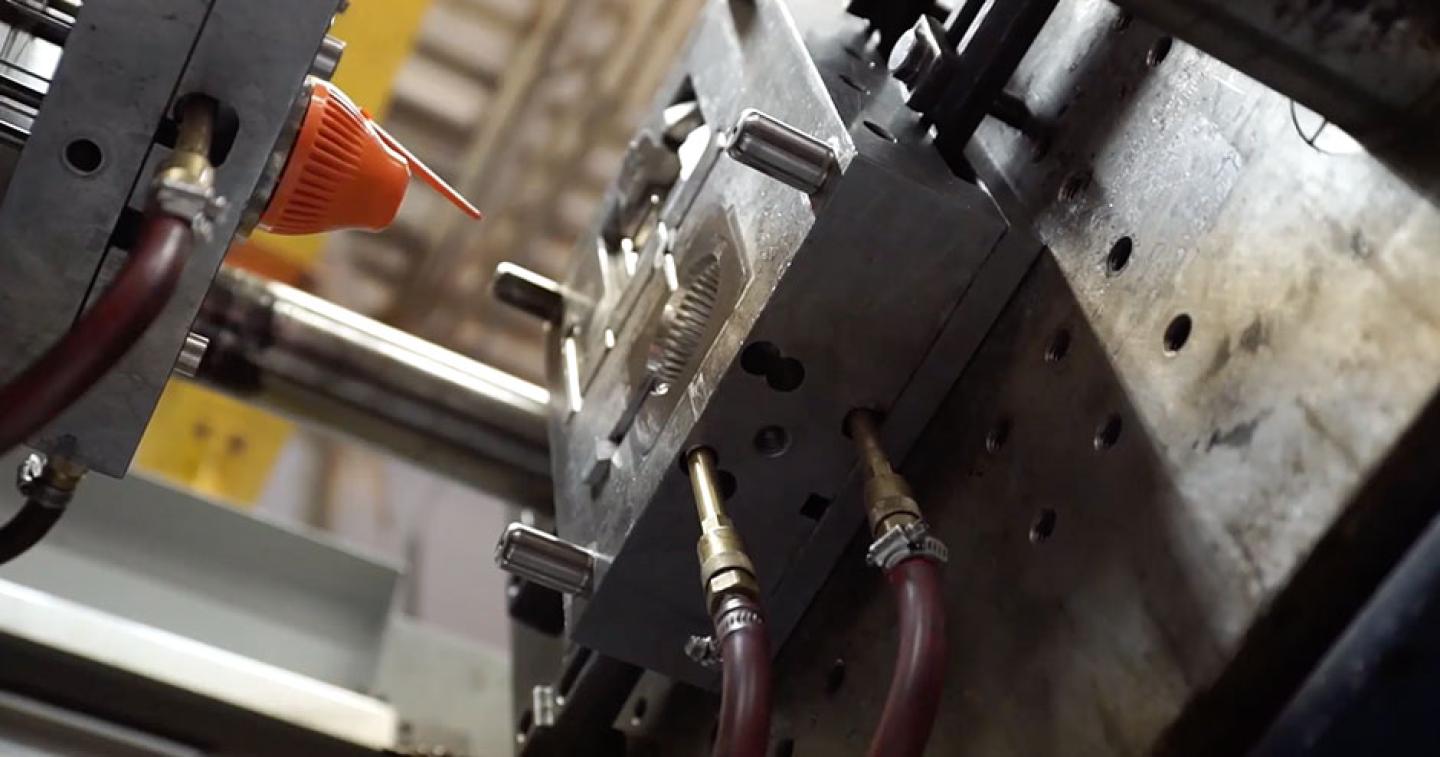

Cnc machining can produce parts with tight tolerances up to 0 025 mm and fine detail from a variety of metal or plastic materials. We specialize in turning and milling and strive to produce the highest quality product. All of these variables come together with the help of toolpaths to successfully produce parts within tolerance. Every machine shop is different and each has unique flooring needs.

Typically they will work best when cutting cavities with a depth of up to 2 3 times their diameter. Improve your milling finish reduce post machining finish work get better looking parts. Protective machine shop flooring for various facilities. It may drop down for a pocket or two but the floors of the pockets and the top of the part are generally smooth planes punctuated by holes and more pockets.

Or cut depth if you re talking the floor of a pocket or surfacing with a face mill and do a separate finish pass. The depth of cut has to be larger than the chip load or you can get rubbing. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. It is important to keep in mind that cnc tools have a limited cutting length.

The best finishes start the chip out fat and then. Machining design associated ltd. Machining deep cavities affects the cost of cnc parts dramatically as a lot of material needs to be removed which is very time consuming. Cnc milling toolpaths are typically categorized 2d 3d 4 axis and 5 axis.

The existing floor condition and age amount of coolant being tracked around by workers shoes level of traffic and actual items being worked on will all affect the type of flooring solution that s best. An operation or toolpath is typically aimed at machining a particular feature on the part and we often refer to the toolpath and the feature by the same name such as a hole or a pocket. The vast majority of parts have this characteristic but for those that don t you ll be doing true 3d machining and to do that you ll want to use a ballnosed endmill.