Microwave Sintering Of Ceramics

Y 2 o 3 al 2 o 3 and mgal.

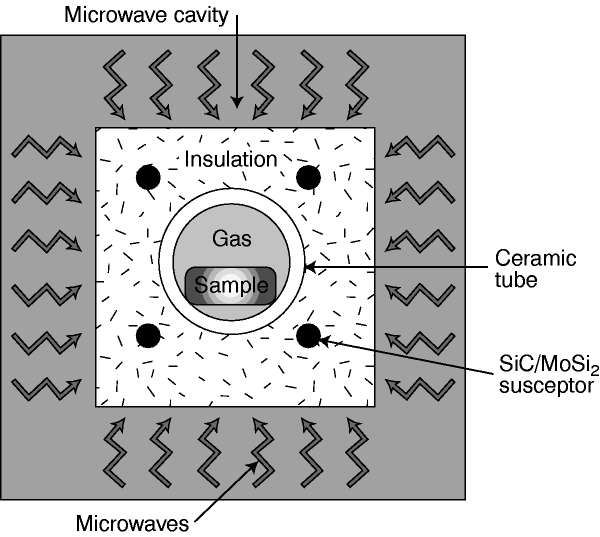

Microwave sintering of ceramics. Hybrid microwave heating is currently investigated for. The heating procedure conditions and characteristic features of ultra rapid microwave sintering have been studied for other oxide ceramics. The observed flash microwave sintering effect is not unique to yb lay 2 o 3 laser ceramics. The first cavity has been used to sinter ceramics zro 2 al 2 o 3 hardmetals wc co metals titanium steel aluminium and cermets.

Sintering of metal and ceramic coatings. Hence microwave sintering is classified as a non conventional sintering technique. Sintering of ceramics ceramic composites cermets and metals. Though microwaves have been in use for many applications for over 60 years their application in ceramic processing involving synthesis sintering melting joining surface modifications etc has developed only in the last twenty years.

It is rather a slow process and takes considerable time to achieve thermal equilibrium and material. Microwave sintering is considered a relatively new ceramic material processing technique that differs significantly from conventional sintering methods due to the nature of the heat transfer mechanisms involved. Microwave sintering of materials is fundamentally different from conventional sintering. Conventional sintering involves radiant resistance and or convection heating followed by transfer of thermal energy via conduction to the inside of the work piece through the thermal conductivity mechanism.

Introduction microwaves are electromagnetic waves with wa velengths ranging from 1m to 1 mm which. Furthermore in many. Souto 2 and ruth h g a. Ultra rapid microwave sintering of al 2 o 3 mgal 2 o 4 and y 2 o 3 ceramics.

Microwave materials processing is recognized for many advantages namely substantial reduction in cycle time resulting in large energy savings selective. Sintering ceramics using microwave radiation a novel technology widely employed in various fields can be an efficient economic and environmentally friendlier approach to improve the. 1 microwave fast sintering of ceramic materials romualdo r. The objective of this study was to examine the feasibility of sintering dental ceramic e g zirconia in a microwave oven and compare the mechanical properties of these with similar materials sintered in a conventional furnace.

Application of microwave heating in ceramic sintering is expanding while the proper in situ temperature measurement is critical since the process is thermally driven 9 10. Sintering of ultrafine powders and nanopowders. Kiminami 2 1department of materials engineeri ng federal university of paraiba 2department of materials engineering federal university of são carlos brazil 1.

.jpg)