Metal Vs Ceramic Quench Rate

The steam blanket slows the quenching rate and hardness obtained in the steel.

Metal vs ceramic quench rate. Preparing articles for hardening 9. Purpose of quenching 2. If you have ever been to a real blacksmith s forge or watched one of the popular metal working reality tv shows you likely have seen the professionals using quenching heat treatments such as oil quenching it differs from other common steel heat treatment processes such as case hardening tempering steel. Internal stresses set up in quenching 7.

Yes crystalline yes free roaming valence electrons tied up in bonds. Mass effect of quenching 6. Gm quenchometer test apparatus. The jominy sample is quenched at one end and the distance from the quench correlates with a specific cooling rate.

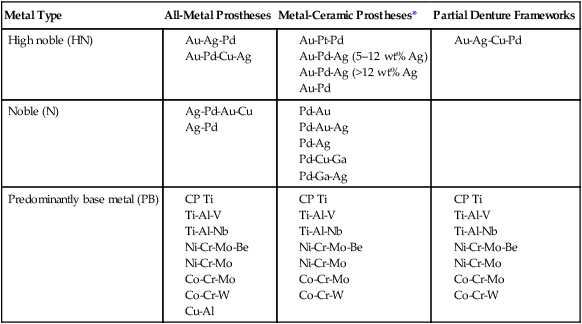

One of the oldest tests to quantify the quench severity of an oil is the gm quenchometer nickel ball test which is conducted according to astm d3520 figure 3. Bates and totten have addressed the selection of quenchants and quenching conditions that will optimize material strength and minimize the potential for distortion 3. Nitrate based most common and chloride based. Mechanism of quenching 5.

However although it is well known that properties such as corrosion resistance are also cooling rate dependent the problem of quenching system evaluation with re. Things you should know. Slower quench rates give thermodynamic forces a greater opportunity to change the microstructure and this often can be a bad thing if that change in the microstructure weakens the metal. If you do know the proper heattreat use it.

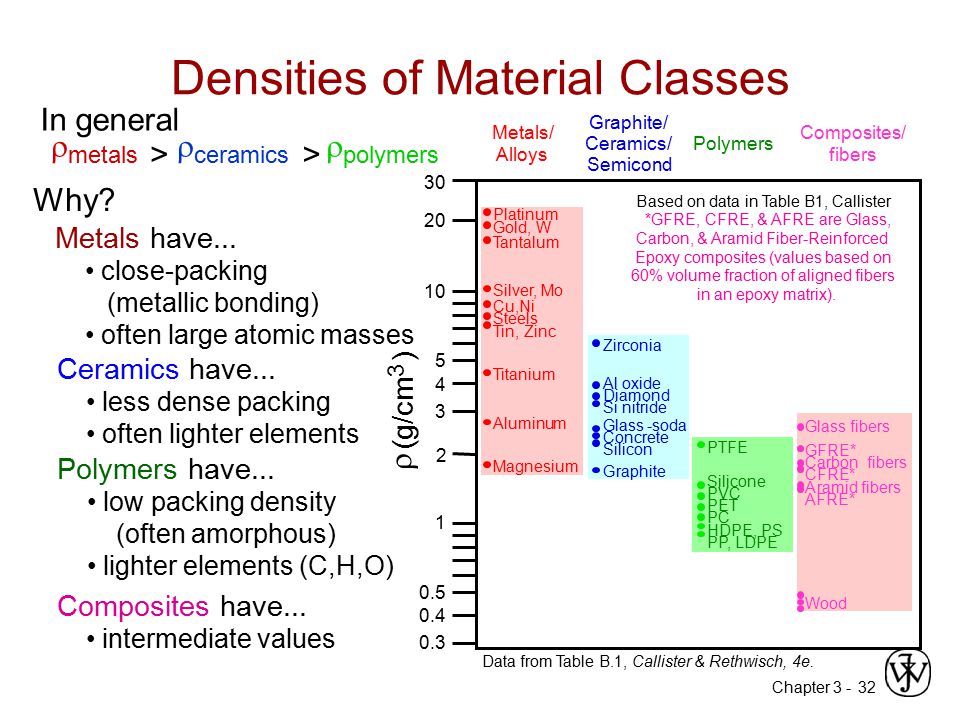

Low shear strength high. Metals property ceramics. Also known as a salt quench as is known to be a more severe quench. Quench and cooling rate martensite only forms if the steel is cooled quickly enough and the necessary cooling rate varies between different steels.

Effect of carbon in hardening steel 4. When considering ceramics vs. Advantages of ceramics vs. A typical elemental analysis report for metal salts contained in a quench oil is shown in table 2.

In this article we will discuss about 1. Greatly reduces the steam jacket that usually forms with plain water quench. Our zirconia based ceramics are the toughest ceramics known to mankind. High tensile strength low.

Sometimes this outcome is preferred which is why different media are used to perform quenching. Many knifegrade alloys will crack or even shatter in water. Quenching metal explained january 15th 2018. Steel components consider that roccera ceramic products outlast the hardest steel by 10 to 20 times with regards to service life.

Hardening of steel by quenching 3. Two types of salt. Opaque optical properties transparent. Metallic type of bonding ionic covalent.