Metal Core Vs Ceramic Core Cat

Yes metal cats are more desirable than ceramic.

Metal core vs ceramic core cat. Capable of withstanding higher operating temperatures than a ceramic core catalytic converter making it the best choice for modified engines up to 40 improvement in exhaust gas flow vs. Metallic vs ceramic catalyst substrates engineers prefer metallic coating companies prefer ceramic. This is done by putting the pipe inside or outside the opening this is one in the company s line of spun cats which come in a variety of shapes and sizes for close fit applications. Of course we chose the premium version.

And yes they are usually more expensive. Ceramic vs metal core dyno d i m not sure of the condition of the ceramic cat during the test so the results aren t 100 valid. I would not say swapping cats would change the sound in any way noticable. As beaver said you probably wouldn t even notice.

In another application a 0 040 diameter 1 0mm er409cb solid mig wire was welded under pulse conditions at 180 amps 20 volts and 19 6 inches per minute. The hjs is the famous top line metal cat and the expensive downpipes usually run that cat. The ceramic catalytic converters such as part mf99659hm are not as strong and usually do not last as long as metallic substrate converters. The cost per pound for the metal cored wire was more than the cost per pound for the solid mig wire but the realized savings more than offset any additional cost for the metal cored wire.

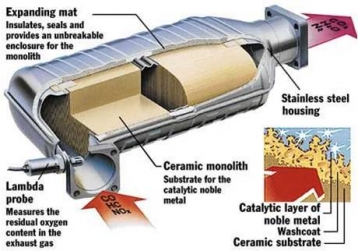

3 200 cell high flow metal core. The ribs form a channel that protects the cushioning mat from direct exposure to exhaust gasses and they hold the ceramic catalyst in proper alignment. Ceramic substrates have been the choice for catalyst coating companies for decades. Typically the ceramic converters are used on obdii vehicles.

Test pipe vs metal core i think this is a more valid example of what differences will be seen between open pipe and 100 cell larger openings in the core metal core. I attached an faq on catalytic converters for you to check out also. Metal core cats can also withstand much more heat and vibration than a standard ceramic core cat making them the ideal choice for high horsepower turbo and supercharged cars. Lap joint where the necks meet the body.

Cell count maybe but probably not. We also had a choice between a typical and less expensive ceramic core and a higher flow metallic substrate. A typical ceramic core converter vibrant metal cats now feature a low profile spun body to make them easier to install in tight spaces.