Metal Ceramic Heater Vs Positive Temperature Coefficient

The positive temperature coefficient of resistance ptcr is the characteristic effect noticed in barium titanate bt based ceramics where a sharp increase in resistivity by several orders of magnitude occurs across a crystallographic phase change from tetragonal to cubic at the curie temperature.

Metal ceramic heater vs positive temperature coefficient. Temperature rating the operating temperature range of metal film resistors range from 65 c to 250 c. The temperature the heater will hold is decided when the material and the heater is produced. Here α has the dimension of an inverse temperature and can be expressed e g. A thermistor is a type of resistor whose resistance is dependent on temperature more so than in standard resistors the word is a combination of thermal and resistor thermistors are widely used as inrush current limiters temperature sensors negative temperature coefficient or ntc type typically self resetting overcurrent protectors and self regulating heating elements positive.

Choosing the right resistor could prevent the need for temperature compensation. In 1 k or k 1. The resistivity of the material increases rapidly with increasing. Ptc ceramic materials are named for their positive thermal coefficient of resistance i e resistance increases upon heating.

It can be fine tuned by changing the voltage to the heater. A temperature coefficient describes the relative change of a physical property that is associated with a given change in temperature for a property r that changes when the temperature changes by dt the temperature coefficient α is defined by the following equation. Ptc stands for positive temperature coefficient. Ptc thermistors are resistors with a positive temperature coefficient which means that the resistance increases with increasing temperature.

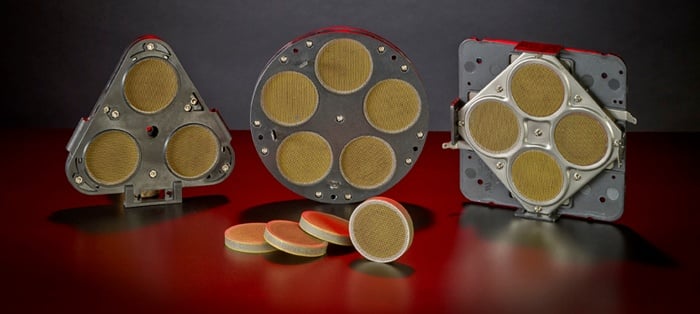

Fin elements or honeycomb forms. They have a lower temperature coefficient compared to carbon composition and carbon film resistors which gives better temperature stability. Ptc thermistors are divided into two groups based on the materials used their structure and the manufacturing process. Self regulating heaters are made from materials with strong positive temperature coefficient ptc characteristics i e.

While traditional fixed resistance heaters employ wires and coils to generate heat ptc heaters use conductive inks printed on thin flexible polymer based substrates. While most ceramics have a negative coefficient these materials often barium titanate and lead titanate composites have a highly nonlinear thermal response so that above a composition. Resistors are available with a tcr that is negative positive or stable over a certain temperature range. Positive temperature coefficient ptc heaters are self regulating heaters that run open loop without any external diagnostic controls.

Average tcr δr r in ppm for a temperature range of 55 till 25 c and 25 till 125 c. Ptc heaters fall into one of two categories. Positive or negative temperature coefficient of resistance.