Metal Ceramic Crown On Cr Co Or Cr Ni

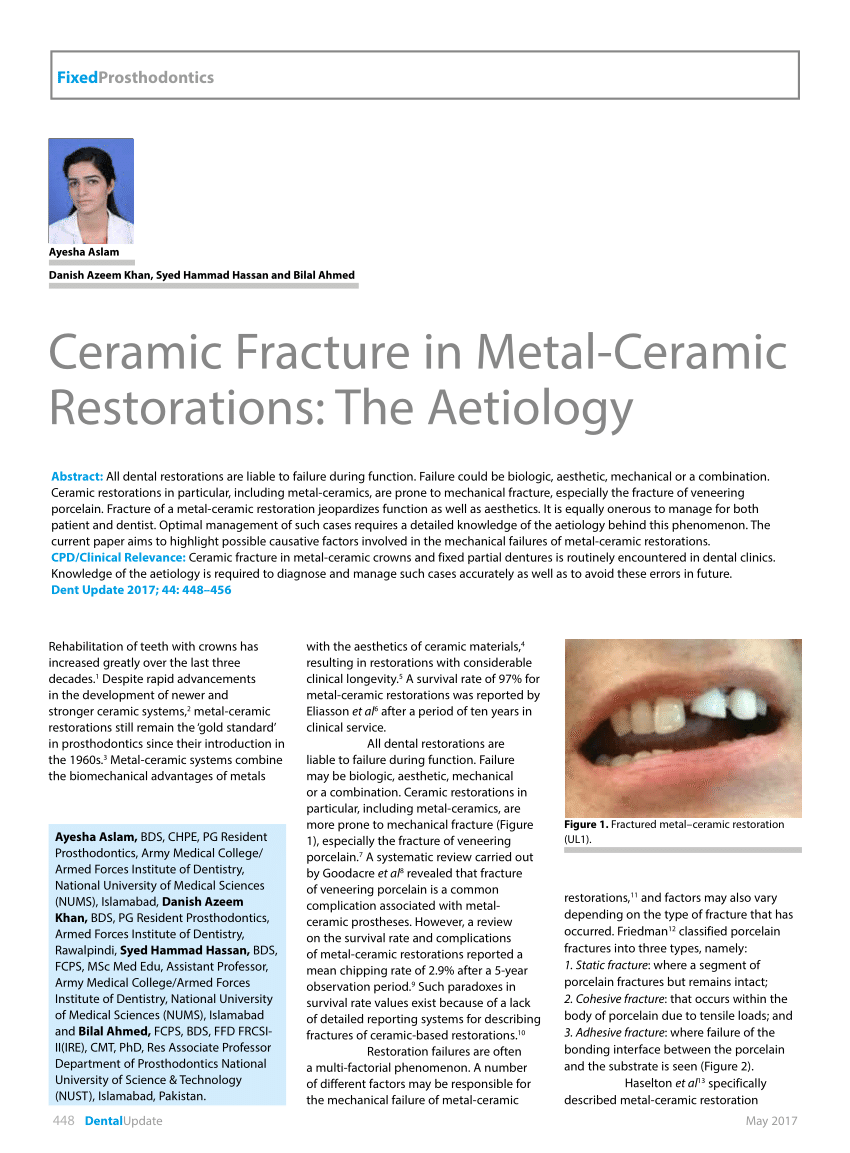

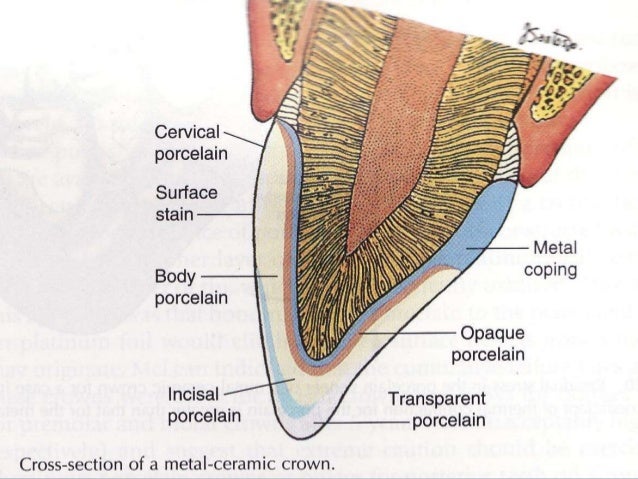

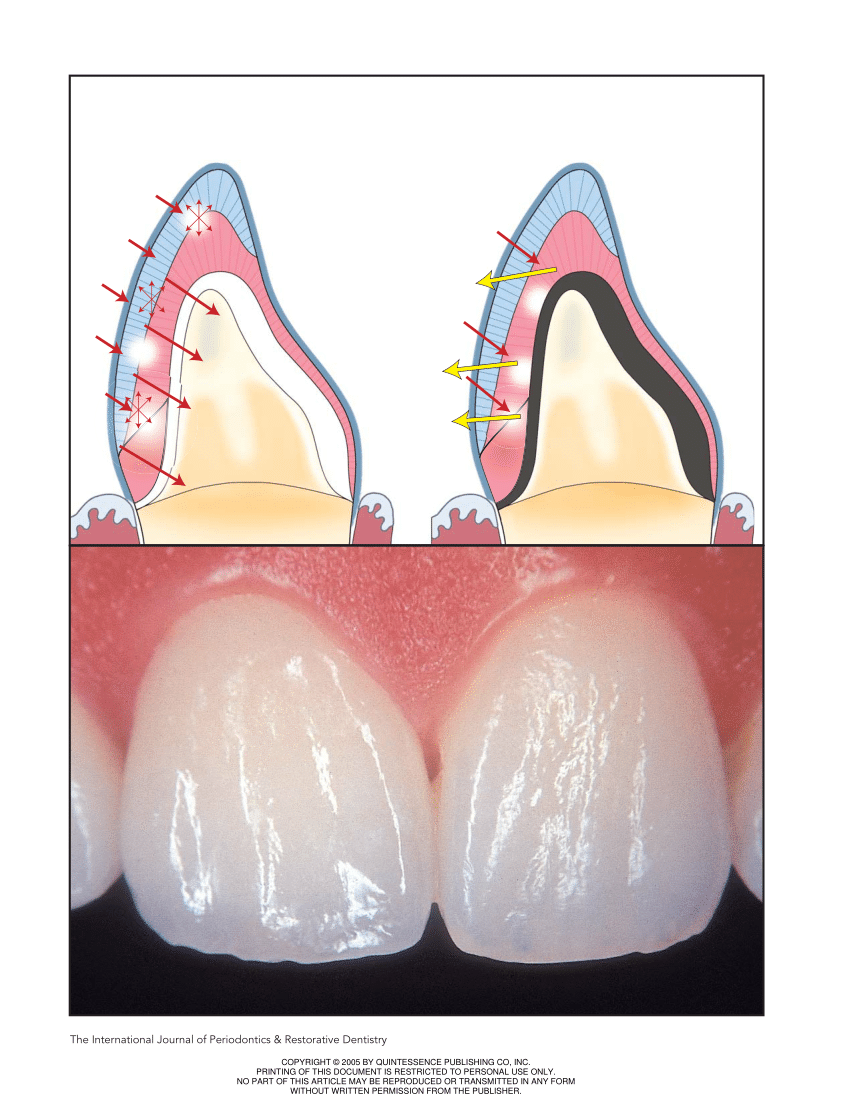

The metal ceramic crown is indicated on teeth that require complete coverage and for which significant esthetic demands are placed on the dentist e g the anterior teeth.

Metal ceramic crown on cr co or cr ni. Studies showed that the bond strength of ceramic to co cr and ni cr alloys ranges from 35 to 95 mpa 13 14the bond strength values obtained in this study for the ni cr alloys were consistent with those of previous studies 10 12 15 16the findings of the present study showed that there was significant reduction in the metal ceramic bond strength for each of the ni cr 664 63n and co cr alloys 497 41n with the addition of recast alloy to the fresh alloy. Because they are metal free all ceramic crowns are usually indicated in the front part of the mouth cavity incisors especially where aesthetic demands are very high. Dimitriadis k et al. Nickel ni chromium cr mercury hg palladium pd and cobalt co are metals which are commonly used in dentistry and have been known to cause allergies.

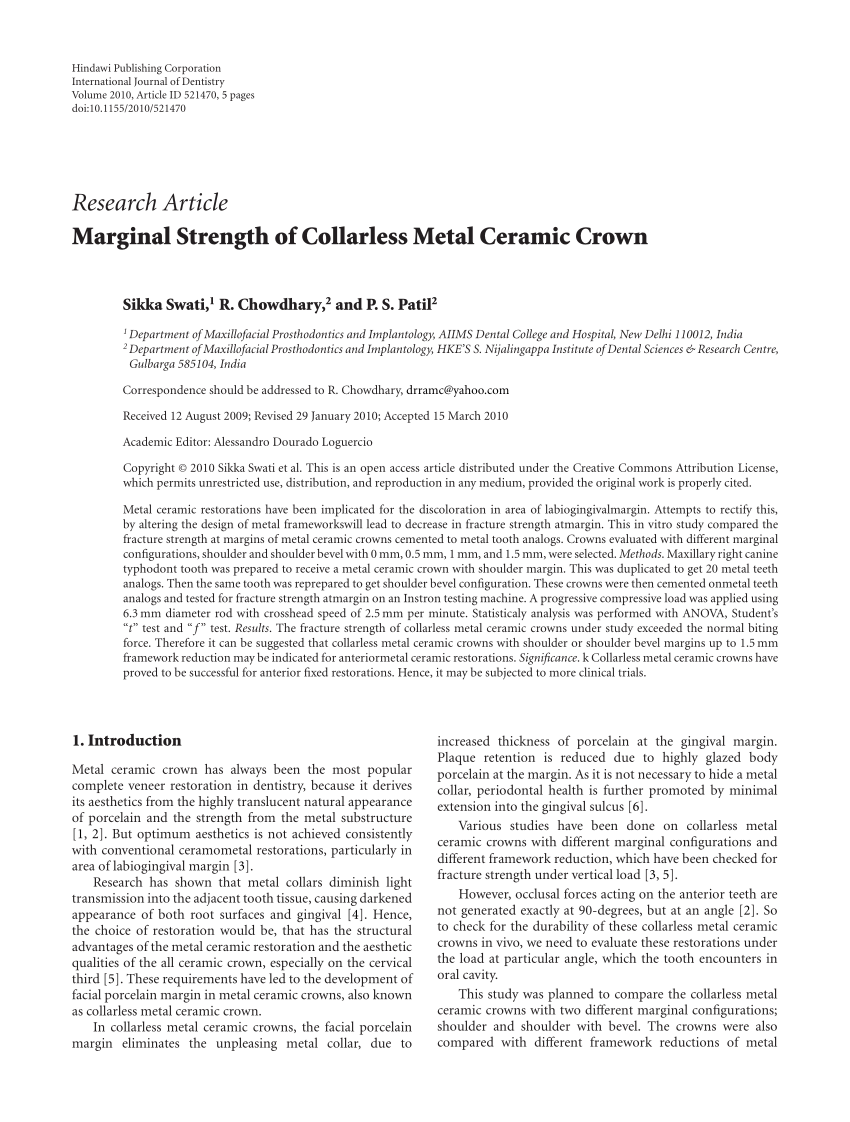

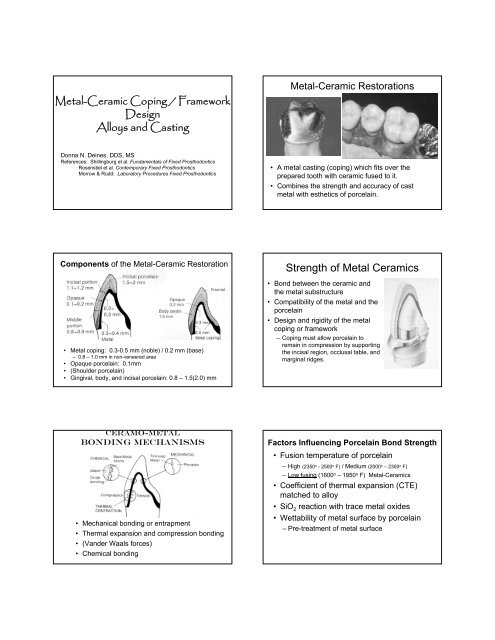

The bonding mechanisms of base metals for metal ceramic crown microstructure analysis of bonding agent and gold bond between porcelain and base metals. Allergic reactions to these materials occur not only in the mucosa of the oral cavity but also on the hands feet and entire body 3 4. Mesa s alloys for ceramics comply with standards iso 9693 1 2012 and iso 22674 2016 they do not contain any toxic elements and in the case of cobalt based alloys they are absolutely nickel free. Dimitriadis k spyropoulos k papadopoulos t.

All ceramic crowns can either be made without a core which is called a porcelain jacket crown. All ceramic crown all ceramic crowns are made entirely of porcelain without any metal frame. And titanium5 6 has increased considerably. Mesa s alloys for ceramics are all highly resistant to corrosion and heat with a low conductivity.

The purpose of this study was to compare shear bond strengths of cast ni cr and co cr alloys and the laser sintered co cr alloy to dental porcelain. These cores are incredibly strong and do not need as much opaque porcelain to cover them. 7 they are more biocompatible and avoid the nickel allergy problems found with ni cr ceramic alloys. Anova followed by tukey hsd multiple comparison test alpha 0 05 was.

Ten specimens were prepared for each group for bond strength comparison. 3 in particular the use of co cr alloys for metal ceramic restorations has become increasingly popular. Unitbond alloy was the thinnest 3 37 microns and wiron 88 alloy was the thickest. It should be recognized however that if esthetic considerations are paramount an all ceramic crown see chapters 11 and 25 has distinct cosmetic advantages over the metal ceramic restoration.

Other porcelain crowns have a ceramic core such as alumina or zirconia. Metal ceramic crowns consisting of metal with a porcelain veneer are popular dental. These crowns rely on the bond between the underlying tooth and porcelain for strength. Were used to study the distribution of elements ni cr mo cu o si sn al in four base alloys.