Metal Ceramic Bonding Ppt

Historically ceramic to metal bonding has been done one of two ways with the use of adhesives or with a soldering or brazing process.

Metal ceramic bonding ppt. Low joining temperatures are. Dissimilar metals metal glass metal ceramic and ceramic glass either directly or through the use of interlayers 1 30 77 78. Micromechanical retention of the metal or ceramic bond to resin is achieved by means of. Adhesives various polymers create adhesive bonds between the ceramic and metal components.

The significant breakthrough came with the publication of a patent by weinstein. The bond is a result of chemisorption by diffusion between the surface oxide layer on the alloy and the porcelain. Metal ceramic bond most important requirement for good long term performance. Chipping of all ceramic restorations are similar to those of ceramic metal restorations.

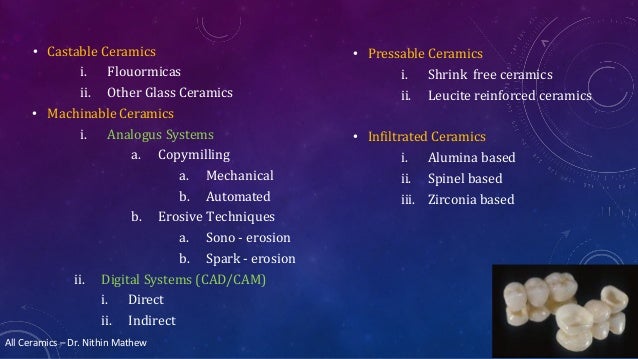

Pre treatment with an adhesion promoter may be necessary. Electronegativity is the capability of the nucleus in an atom to attract and retain all the electrons within the atom itself and depends on the number of electrons and the distance of the electrons in the outer shells from. Porcelain fracture management glass ceramics which are indicated for inlays onlays veneers and monolithic crowns. It offers numerous points of interest mostly the strength of the bonding line which is equivalent to the base metals.

Another possibility is bonding the ceramic to a metal substrate such that these microscopic cracks are effectively eliminated with the consequence that the structure is considerably stronger. The bond strength test was done according to iso. Roughening of surface interface also increases the bond strength increases surface area of wetting for porcelain. The joint strengths are generally lower than metal to metal bonds and the structures vary with the substrate materials.

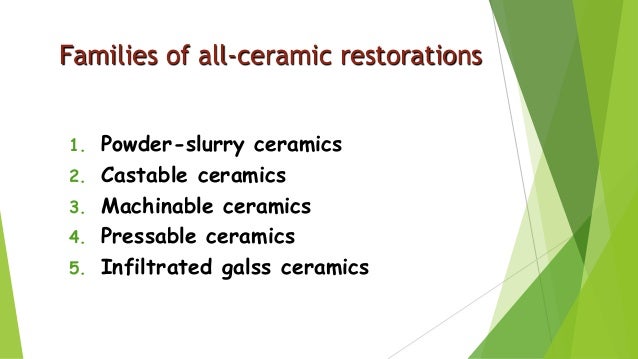

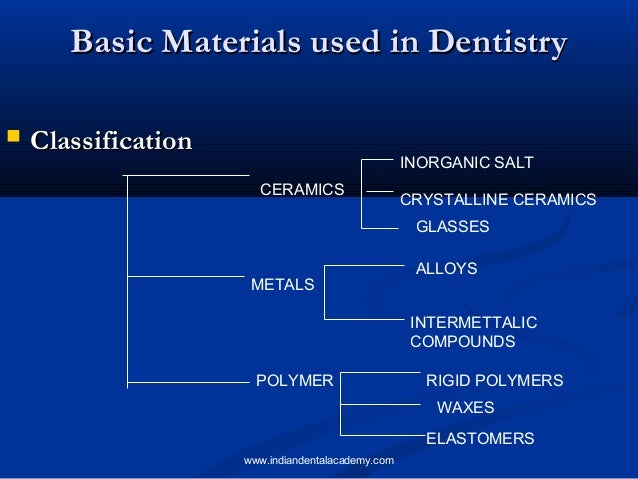

The aim of this study was to compare the influence of a metal ceramic bonding agent for co cr alloys on the bond strength of metal ceramic systems. Air abrasion with the intraoral sandblaster. Because of differences in strength and requirements. There are two major categories of all ceramic materials.

However significant bonding strengths are achieved both with and without. Ceramic to metal bonding. Diffusion bonding is primarily employed in the joining of dissimilar materials i e. S bond alloys can join a variety of ceramics and have the capability to join ceramics to metals other ceramics and glasses.