Max Phase Ceramics Are Used In Various Applications Due To

In fact properties of ceramics and glass can be tailored to specific applications by modifying composition including creating composite materials with metals and polymers and by changing processing parameters.

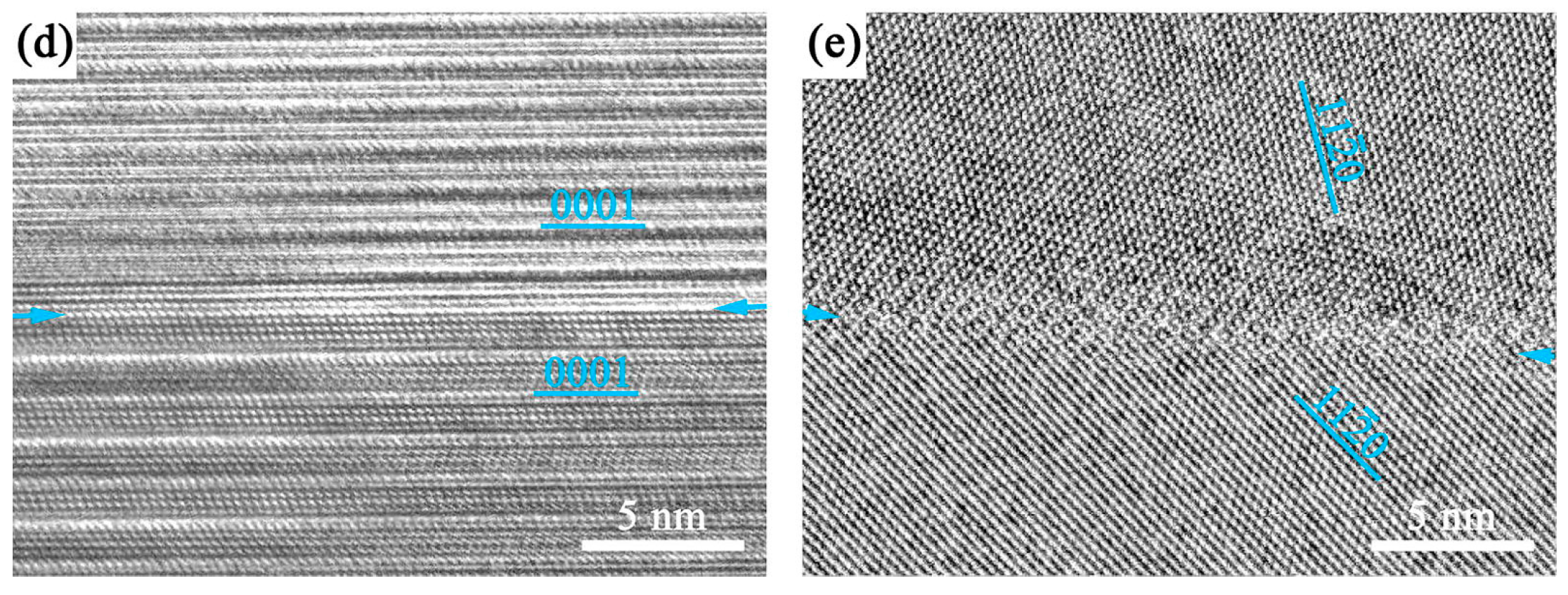

Max phase ceramics are used in various applications due to. But it is just this bonding nature of ceramics that directly results in their inherent brittleness and difficulty in machining. These material properties are utilized to produce number of commercial and domestic products such as pottery bricks advanced functional items etc. Applications of ceramicsziad zohdy 2. The most oxidation resistant max phase is ti 2 alc because it forms a stable and protective al 2 o 3 layer that can withstand thermal cycling up to 1 350 c for 10 000 cycles without spallation or cracking figure 4 33 the.

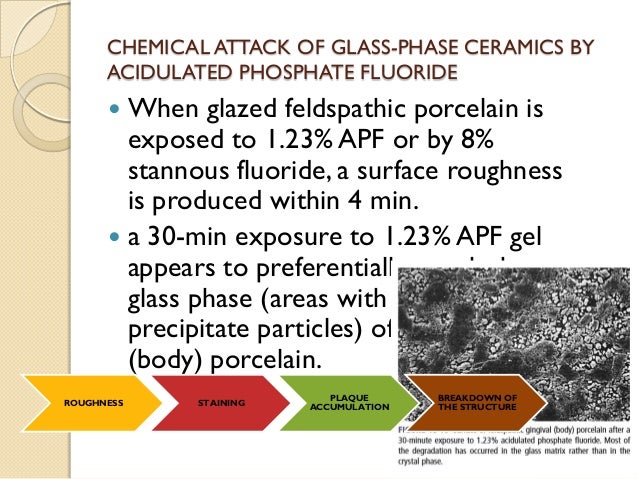

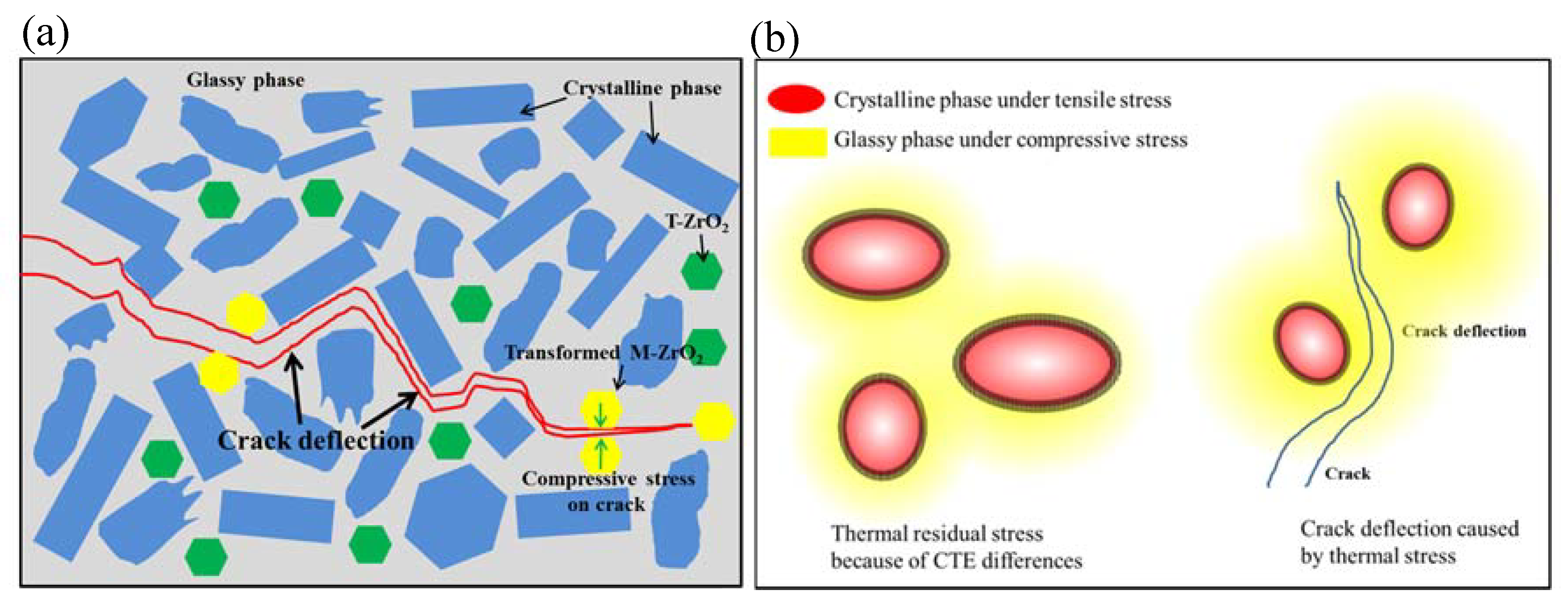

Ceramic materials can be identified by their general properties like high hardness brittleness chemical stability and low thermal conductivity. Al 2 o 3 zro 2 aln sic si 3 n 4 ferrites piezoceramics and fibre composites. A ceramic material may be defined as any inorganic crystalline material compounded of a metal and a non metal ceramics can be classified as crystalline ceramics non crystallineceramics crystalline ceramic materials are not amenable to a great range ofprocessing. L yongli in ceramic matrix composites 2006.

Applications of ceramics 1. Chapter 13 applications and processing of ceramics study guide by myx dang includes 31 questions covering vocabulary terms and more. Advanced ceramics and traditional ceramics are the main categories of ceramic materials. Quizlet flashcards activities and games help you improve your grades.

Bios self cleaning add circle remove circle the hydrotect technology has been licensed out to over 100 manufacturers all over the world in the most diverse areas of application from car making to building. These are typical properties. They can also be amorphous or have inhomogeneous chemical composition which develops upon pyrolysis of organic precursors the high process temperatures required for making cmcs preclude the use of organic metallic or glass fibers only fibers stable at temperatures above 1 000 c 1 800 f can be used. Depending on the specific application the requirement profiles are very different and a correspondingly wide range of suitable high grade ceramic materials is available for selection.

Ceramic fibers in cmcs can have a polycrystalline structure as in conventional ceramics. The table below provides a summary of the main properties of ceramics and glass. Aluminium oxide al 2 o 3 and zirconia zro 2 are the most commonly used engineering grade oxide ceramics with alumina being the most used ceramic by far in terms of both tonnage and value. A reduced environmental impact due to limited use of raw materials and energy resources in the production process.

.jpg)