Matting Agents For Waterborne Coatings

This article focuses on those based on sio2 from.

Matting agents for waterborne coatings. In order to fully optimize this important parameter michelman has recently developed two wax dispersions. Syloid aq silicas impart high chemical resistance excellent clarity and good scratch resistance and burnishing to wood coatings that produce natural looking deep matte finishes on fine wood furniture cabinets and floors. Waxes products based on polytetrafluorethylene ptfe are also used as matting agents. 50 laser diffraction acematt 810 is an untreated coarse grained precipitated silica.

Because of the chemical and physical characteristics of this group of materials no comparison can be made of their effects and they cannot simply replace silicate based matting agents. Both dispersions aid in imparting a matting effect to most aqueous coatings and varnishes while enhancing other properties such as abrasion resistance and water repellency. Architectural paints and coatings. Ppg lo vel silica flatting and matting agents reduce the gloss of a variety of products including coatings paints lacquers varnishes and inks while providing lower viscosity and better stir in capability.

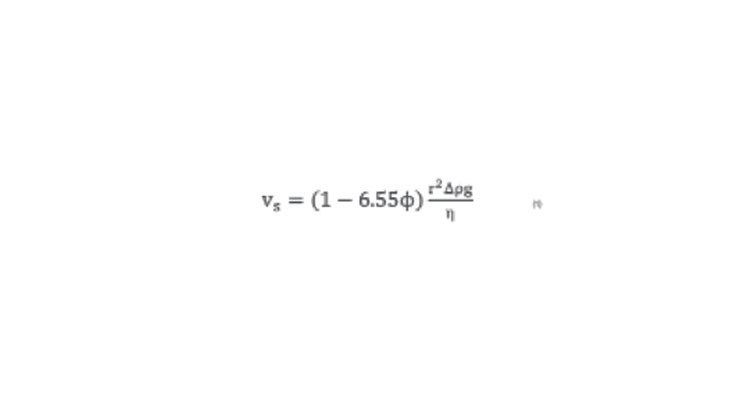

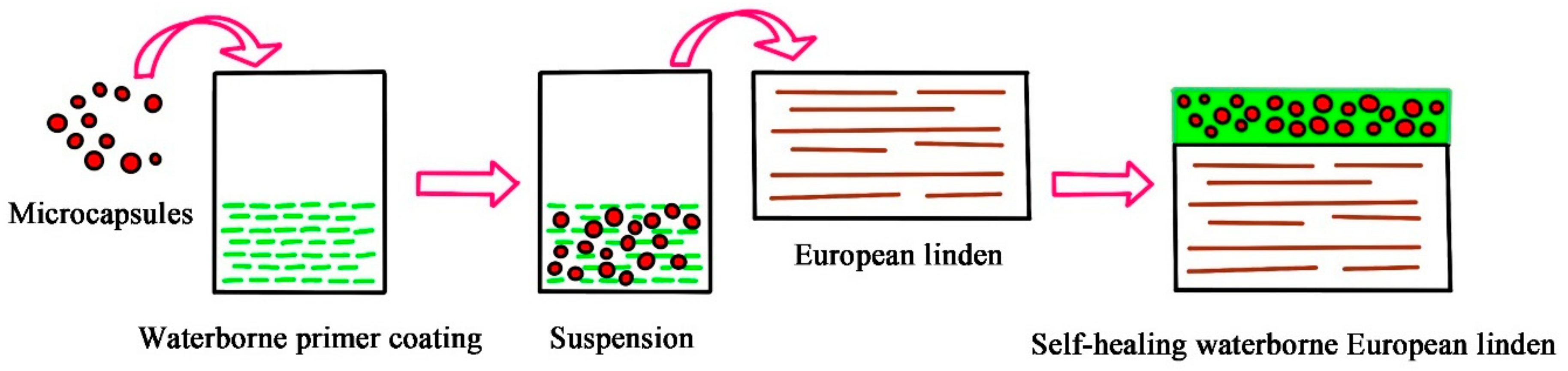

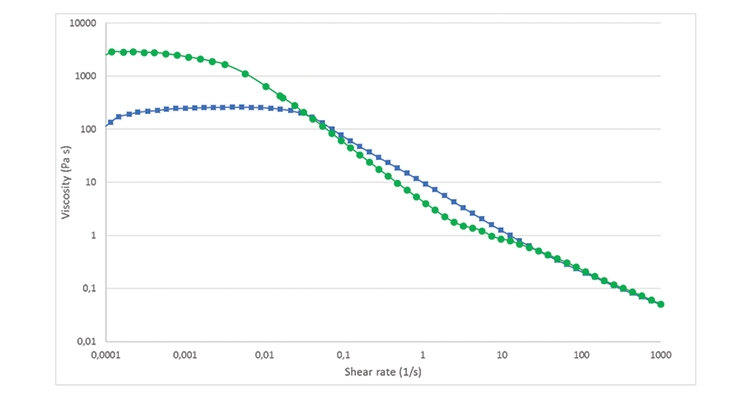

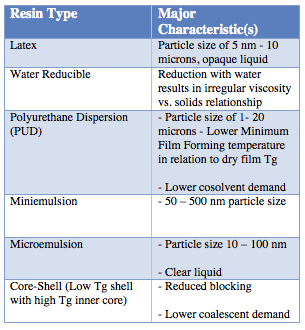

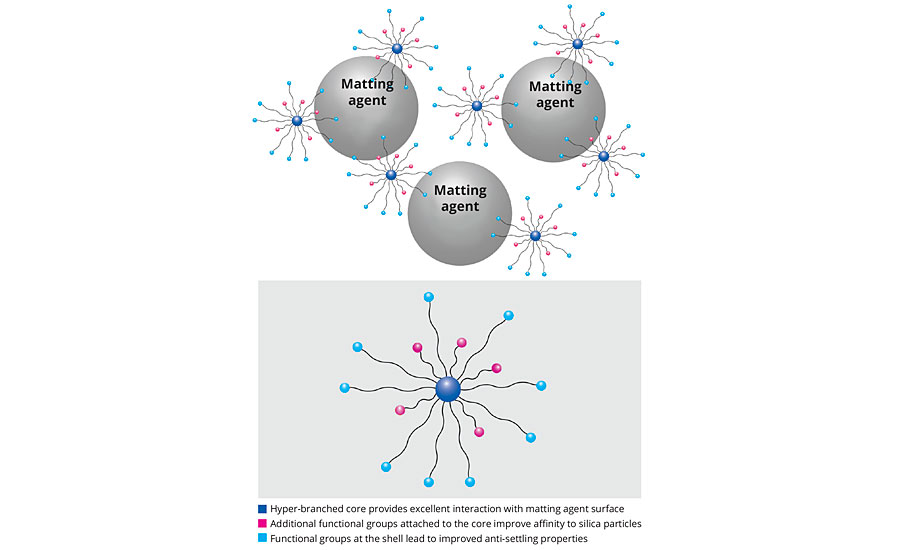

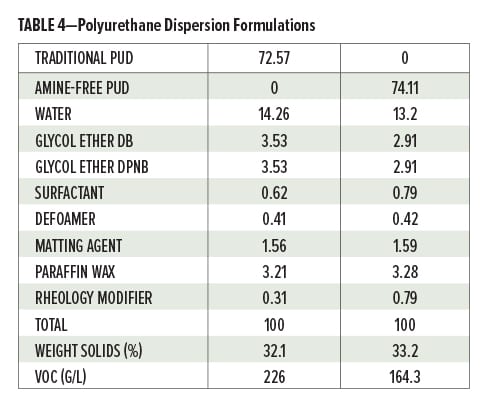

Settling of pigments and matting agents without significantly affecting the viscosity of the waterborne coating. Waterborne resin technology for high performance and lower vocs efficient resins and opaque polymers to optimize titanium dioxide needs rheology modifiers to improve application silicone additives to help with foam control slip leveling and waterproofing. Waxes as matting agent in paints coatings and inks waxes based on polyethylene polypropylene carnauba and amide are mostly used. Michem guard 349 and michem guard 350.

The finely dispersed silica aggregates help pigment filler and matting agent particles stay dispersed and keeps them from re agglomerating and hard packing. It is often used in can and coil coatings decorative and industrial coatings. This highly efficient matting agent is especially suitable for pigmented systems with low sheen 85 reflectometer value 60 reflectometer value. Figures 3 4 and 5 show the results of using.

This article focuses on matting agents based on sio2 from precipitated and gel processes which are marketed specifically for the uv coatings segment matting agents or additives to increase surface roughness have evolved over the decades based on a variety of sources and include ground polymeric types to those based on silicon dioxide. Polymethyl urea resin for matting of coated surfaces. Our deuteron and pergopak matting agents are organic thermoset urea methanal polymers supplied in the form of finely ground powder. In contrast to silicas waxes modify the surface properties of a paint film by floating to the top of the surface.